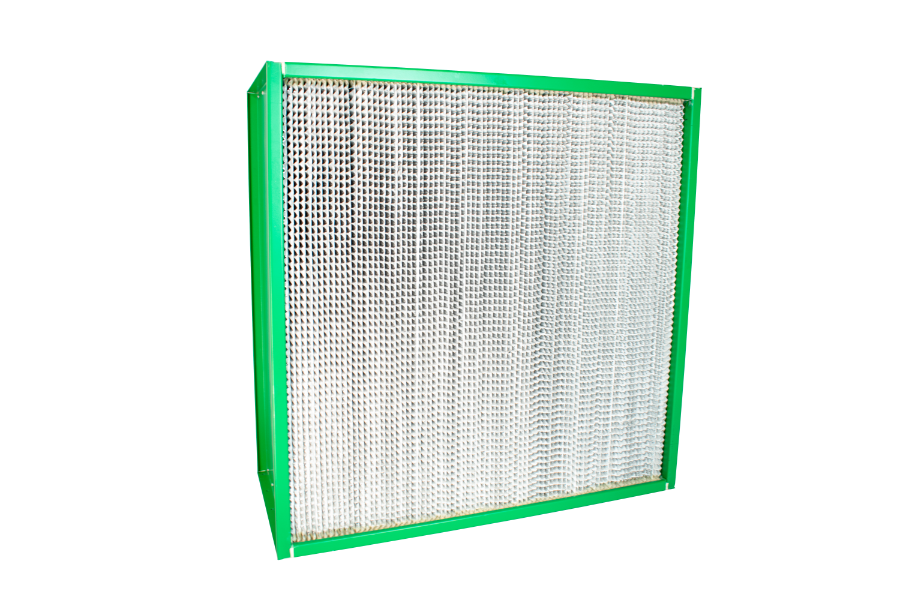

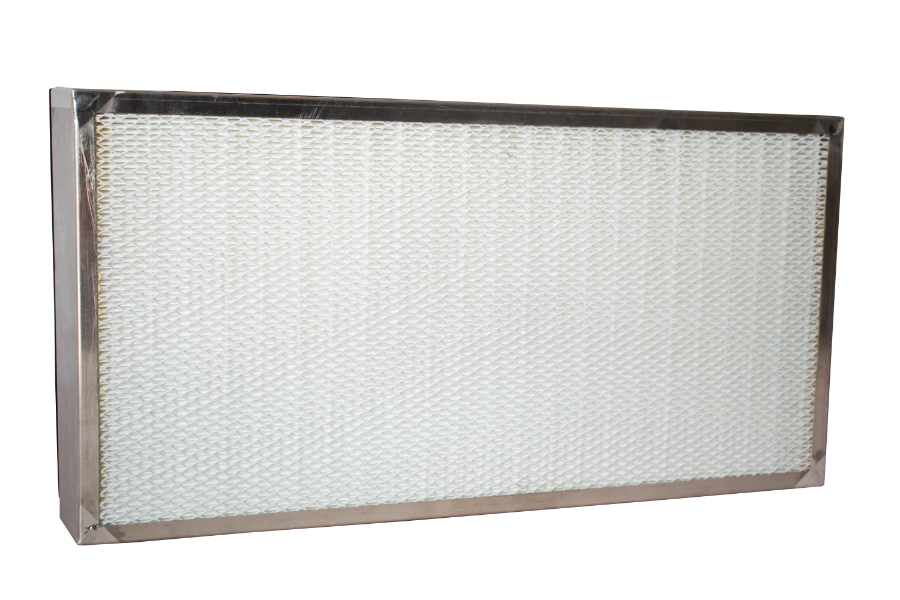

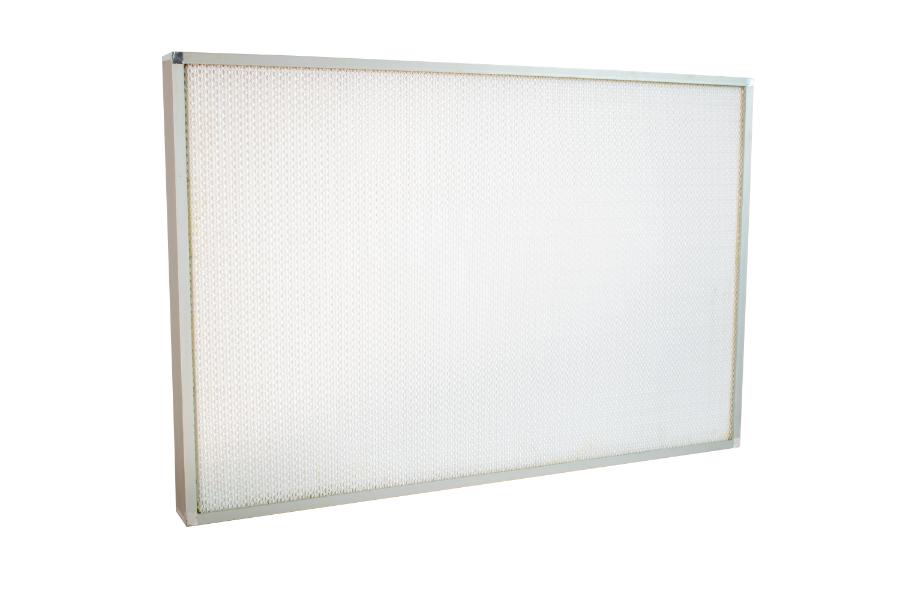

Air Filters

Indoor Air Quality (IAQ) is fundamental to the sustained advancement of critical industries engaged in Healthcare, Pharmaceuticals, Semiconductors, Electronics, Aerospace and other such facilities where airborne contaminants can severely undermine the health of the building occupants, and damage contamination sensitive manufacturing processes.

Hospitals/Healthcare

Studies have established that patients in controlled environments generally show rapid physical improvements than do those in uncontrolled environments. Maintaining IAQ is critical for preventing the spread of infectious diseases. Recovering patients suffer from weakened immune systems, vulnerable to airborne contaminants. Poor IAQ can lead to the transmission of pathogens, which can result in Hospital-Acquired Infections (HAI), prolonging patient stays, resulting in increased healthcare costs.

In this context, a well designed building HVAC system with sufficient air changes and most importantly, incorporating a series of HEPA filtration is critical for preserving the life of patients, medical practitioners and other hospital occupants.

Pharmaceuticals

The pharma sector and related industries are tightly governed by the FDA and local regulations to strictly adhere to cleanroom cleanliness classification levels as defined under ISO 14644-1. Not limited to regulatory and statutory compliance alone, failing to maintain a virtually particulate-free environment inside pharmaceutical manufacturing facilities can result in contaminated and potentially fatal drug formulations reaching patients and end consumers.

HEPA filters are at the heart of a pharmaceutical cleanroom air filtration system to ensure contaminants like moulds, spores, bacteria, pollen, or volatile organic compounds are eliminated at source and statutory compliances are sufficiently maintained.

Semiconductors & Microelectronics

Fabricating semiconductor wafers and integrated circuits for electronic applications involves complex processes worth billions of dollars in capital expenditure (CAPEX). Should there be any inventory rejects owing to airborne contamination during fabrication, the costs could potentially run into millions.

Processes like wafer fabrication, photolithography, etching, doping, depositions etc., are repeated many times over in a controlled cleanroom environment for greater precision and quality control and contamination is the biggest source of concern. There is simply no room for deviating from contamination control protocols. Key to operating a cleanroom in semiconductor fabs and electronics assemblies is HEPA filters in conjunction with pre-filters and secondary filters at different points in the building HVAC systems. HEPA filters guarantee total airborne particulate control up to 0.3 micron, eliminating any dust or suspended matter that might damage the silicon wafers or electronic components.

Why Alpha Linear?

With over 30 years of experience in cleanroom equipment design and manufacturing, Alpha Linear has evolved into a premier manufacturer of HEPA filters, primary, and secondary air filters for industrial and commercial ventilation application. Feel free to explore our range of filters and reach out to us for further consultation.